Our Products

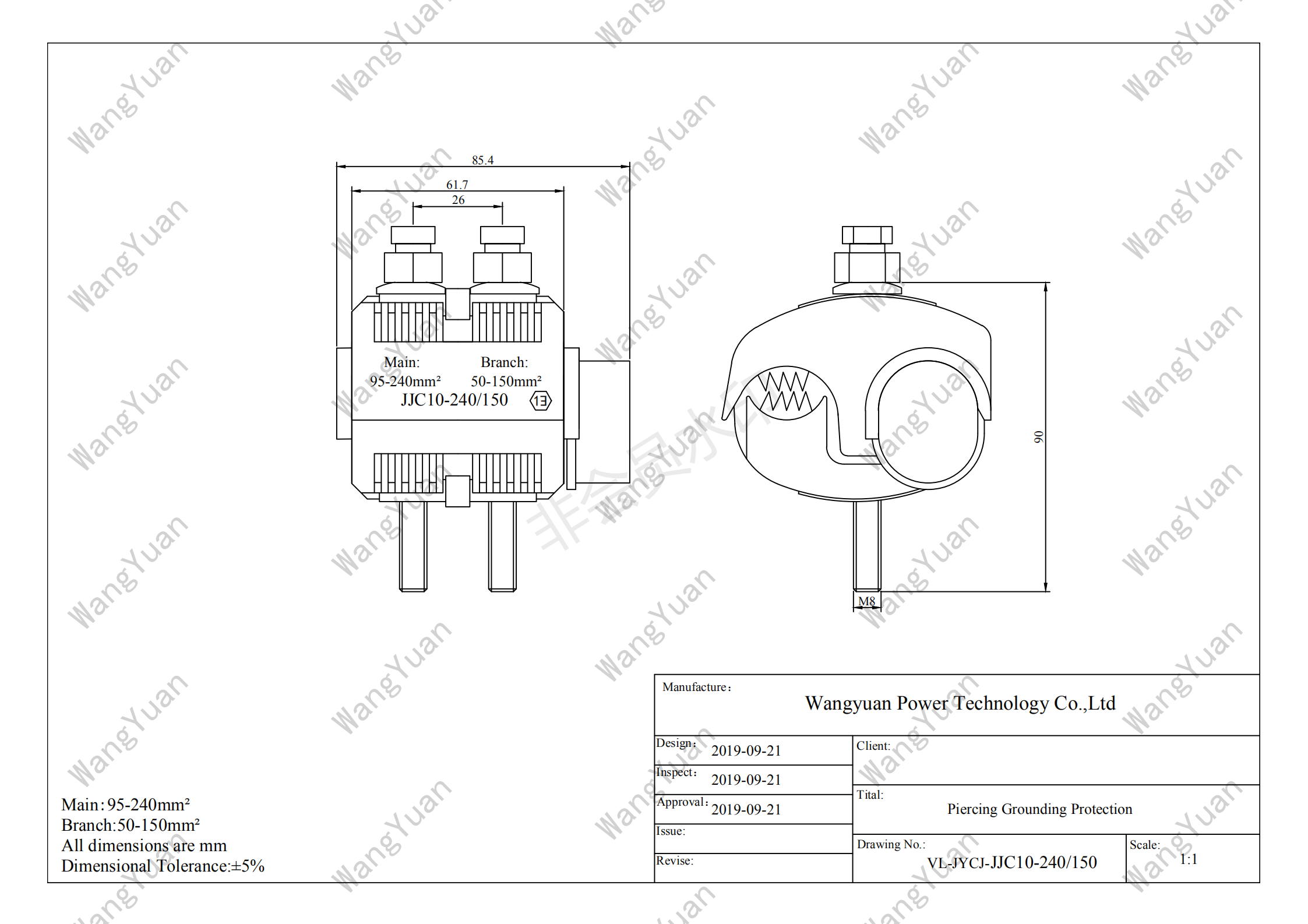

Insulated piercing conector JJC10-240/150

BASIS DATA

| Catalog No. | Application cable | Dimensions(mm) | Nominal current | Bolt No . piece | |||

| Main line | Branch line | A | B | H | |||

| JJC10-300/300 | 150~300 | 150~300 | 100 | 85 | 136 | 600 | 2 |

| JJC10-300/150 | 150~300 | 35~150 | 92 | 83 | 118 | 342 | 2 |

| JJC10-240/240 | 95~240 | 95~240 | 90 | 85.5 | 113 | 476 | 2 |

| JJC10-240/150 | 95~240 | 50~150 | 85.5 | 83 | 113 | 342 | 2 |

| JJC10-240/50 | 95~240 | 16~50 | 76 | 83 | 11.3 | 162 | 2 |

| JJC10-185/50 | 95~185 | 16~50 | 78.5 | 80.5 | 11.3 | 162 | 2 |

| JJC10-95/70 | 25~95 | 16~70 | 68 | 82.5 | 97.5 | 207 | 2 |

|

The Guide For Insulation Piercing Connectors Chapter 1 –Introduction Of Insulation Piercing Connectors |

Chapter 1 –Introduction Of Insulation Piercing Connectors

Piercing connector, simple installation,need not strip the cable coat;

Moment nut,piercing pressure is constant,keep good electric connection and make no damage to lead;

Self-seam frame,waterproof,waterproof,and anti corrosion,extend the using life of insulated lead and connector;

Adopted special connecting tablet apply to joint of Cu(Al)and Al;

Chapter 2–Performance Testing Of Piercing Connector

Mechanical performance:the grip force of the wire clamp is 1/10 bigger than the break force of the lead.It comply with GB2314- 1997;

Temperature rise performance: Under the condition of big current,the temperature rise of connector is less than that of connection lead:

Heat circle performance 200 times per second, 100A/mm² big current,overload,the change of connection resistance is less than 5%;

Wetproof insulation performance:under the condition of S02 and salt fog.it can do three times of fourteen days circle testing;

Environmental aging performance: under the circumstance of ultraviolet, radiation,dry and moist,expose it with change of temperature and heat impulse for six weeks.

Chapter 3-The Reason Of Choosing Insulation Piercing Connector(IPC)

◆Simple installation

Can be branch of cable without striping the insulated coat and the joint is completely insulated,Make brance in the random location of cable without sutting off the main cable Simple and reliable installation,just need sleeve spanner ,can be installed with on live line;

◆Safe use

The joint has good resistance to distortion,quake fire wet,electrochemical corrosion and aging,need no maintenance,Has been used successfully for 30years;

◆Economical cost

Small installation space save the cost of bridge and land construction In structural application ,there is no need terminal box ,junction box and return wire of cable.save cable cost,The cost of cables and clamps is lower than other power supply system.

Chapter 4 –Installation Steps Of Insulation Piercing Connectors

1.Adjust the connector nut to suitable location

2.Put the branch wire into the cap sheath fully

3.Insert the main wire,if there are two lays of insulated lay in the main cable should strip a certain length of the first insulated lay from inserted end

4.Turn the nut by hand,and fix the connector in suitable location

5.Screw the nut with the sleeve spanner

6.Screw the nut continually until the top part is cracked and dropped down

HOT-SALE PRODUCT

Quality First, Safety Guaranteed